Evaporator Fouling . fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. Clay senior process consultant jacobs engineering slide 2. evaporator fouling david t. evaporator fouling is a common, chronic problem during maize starch and ethanol production. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and.

from www.lcicorp.com

evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling is a common, chronic problem during maize starch and ethanol production. Clay senior process consultant jacobs engineering slide 2. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. evaporator fouling david t.

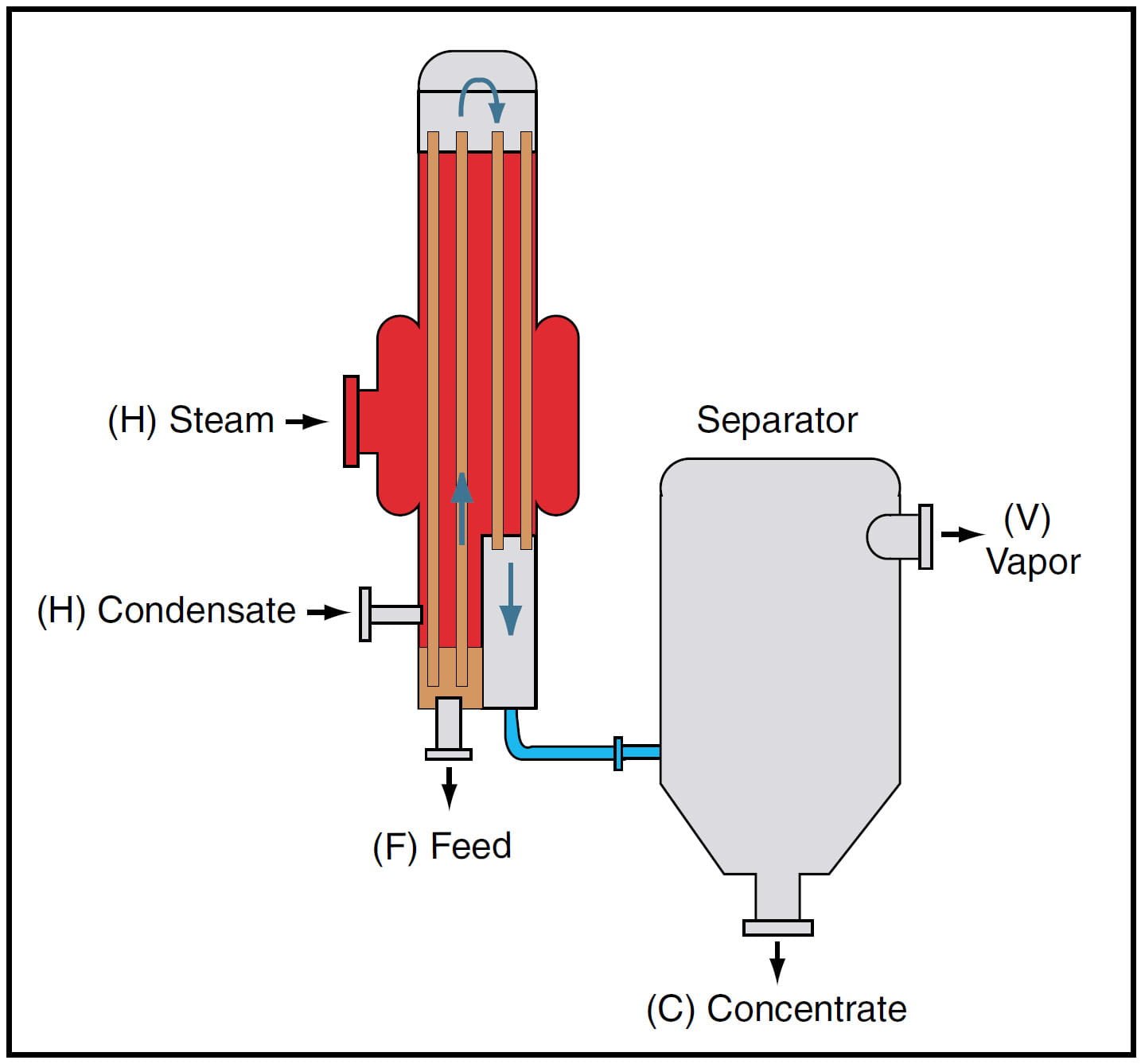

Selecting Evaporators for Process Applications

Evaporator Fouling fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling david t. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. evaporator fouling is a common, chronic problem during maize starch and ethanol production. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. Clay senior process consultant jacobs engineering slide 2.

From www.semanticscholar.org

[PDF] Study of Black Liquor Evaporator Fouling at Södra Cell Värö Evaporator Fouling evaporator fouling is a common, chronic problem during maize starch and ethanol production. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. Clay senior process consultant jacobs engineering slide 2. fouling is the. Evaporator Fouling.

From www.researchgate.net

(PDF) 380435 Evaporator Fouling Tendencies of Thin Stillage from the Evaporator Fouling evaporator fouling is a common, chronic problem during maize starch and ethanol production. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. many of the fouling problems that occur in black liquor. Evaporator Fouling.

From klarenbv.com

What is Fouling & Scaling in Heat Exchanger Klaren Technology Evaporator Fouling fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. evaporator fouling is a common, chronic problem during maize starch and ethanol production. many of the fouling problems that occur in black liquor. Evaporator Fouling.

From fabexeng.com

Agitated Thin Film Evaporator (ATFE) Fabex Engineering Evaporator Fouling evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. evaporator fouling david t. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. Clay senior process consultant jacobs engineering slide 2. fouling of evaporator coils affects heat transfer, increases pressure. Evaporator Fouling.

From www.reapterqd.com

Principle of cleaning to prevent fouling of plate heat exchanger Evaporator Fouling fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. Clay senior process consultant jacobs engineering slide 2. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling was simulated by reducing the air flow rate and it was expressed. Evaporator Fouling.

From klarenbv.com

What is Fouling & Scaling in Heat Exchanger Klaren Technology Evaporator Fouling fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. evaporator fouling david t. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. evaporator fouling is a common, chronic problem during maize starch and ethanol production. many of. Evaporator Fouling.

From caloris.com

Chronic Evaporator Tube Fouling Can be Diagnosed and Permanently Fixed Evaporator Fouling evaporator fouling is a common, chronic problem during maize starch and ethanol production. Clay senior process consultant jacobs engineering slide 2. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. . Evaporator Fouling.

From klarenbv.com

All About Multi Effect Evaporator Cleaning, Operation, Forward Feed Evaporator Fouling Clay senior process consultant jacobs engineering slide 2. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate,. Evaporator Fouling.

From www.academia.edu

(PDF) The impact of evaporator fouling and filtration on the Evaporator Fouling fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. evaporator fouling david t. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. Clay senior process consultant jacobs engineering slide 2. evaporator fouling is a common, chronic problem during maize starch and. Evaporator Fouling.

From www.semanticscholar.org

[PDF] Study of Black Liquor Evaporator Fouling at Södra Cell Värö Evaporator Fouling many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. evaporator fouling david t. evaporator. Evaporator Fouling.

From www.semanticscholar.org

[PDF] Study of Black Liquor Evaporator Fouling at Södra Cell Värö Evaporator Fouling fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling david t. Clay senior process consultant jacobs engineering slide 2. evaporator fouling was simulated by reducing the air flow rate and it. Evaporator Fouling.

From www.semanticscholar.org

[PDF] Study of Black Liquor Evaporator Fouling at Södra Cell Värö Evaporator Fouling fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. Clay senior process consultant jacobs engineering slide 2. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a. Evaporator Fouling.

From www.semanticscholar.org

[PDF] Study of Black Liquor Evaporator Fouling at Södra Cell Värö Evaporator Fouling many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. Clay senior process consultant. Evaporator Fouling.

From whatispiping.com

Heat Exchanger Fouling or Scaling Its Causes, Consequences, and Evaporator Fouling evaporator fouling david t. Clay senior process consultant jacobs engineering slide 2. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat transfer surfaces. fouling of evaporator coils affects heat transfer, increases pressure. Evaporator Fouling.

From altumtechnologies.com

Fouling Removal Solutions for Evaporators Altum Technologies Evaporator Fouling evaporator fouling is a common, chronic problem during maize starch and ethanol production. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. Clay senior process consultant jacobs engineering slide 2. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. . Evaporator Fouling.

From klarenbv.com

Mechanical Vapor ( MVR ) Evaporator System , Fouling Evaporator Fouling many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling david t. Clay senior process consultant jacobs engineering slide 2. evaporator fouling is a common, chronic problem during maize starch and ethanol production. evaporator fouling was simulated by reducing the air flow rate and it was expressed. Evaporator Fouling.

From altumtechnologies.com

Fouling Removal Solutions for Evaporators Altum Technologies Evaporator Fouling fouling of evaporator coils affects heat transfer, increases pressure drop, reduces system airflow rate, and. evaporator fouling david t. evaporator fouling is a common, chronic problem during maize starch and ethanol production. Clay senior process consultant jacobs engineering slide 2. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or between heat. Evaporator Fouling.

From uspto.report

Process for reducing fouling in evaporators in lithium hydroxide Evaporator Fouling Clay senior process consultant jacobs engineering slide 2. many of the fouling problems that occur in black liquor evaporators operating above 50% total solids content. evaporator fouling was simulated by reducing the air flow rate and it was expressed as a percent reduction. fouling is the result of organic matter (fibers, lignin, soap, aq) collecting on or. Evaporator Fouling.